Validation & Verification Services (V&V)

BioFluid offers GMP services as part of the qualification and validation of plants, computer systems and processes in the pharmaceuticals industry, consulting for the introduction of GMP compliant processes in engineering & production, Qualification & Validation

- Conducting basic & detailed Risk assessment

- Vendor Qualification & Procurement assistance

- Preparation of Validation master plan

- Preparation of DQ reports, IQ & OQ protocols & reports

- Performance qualification

- Process validation

- Cleaning validation

- Planning, coordination and performance of all qualification / validation activities

- Computer system validation

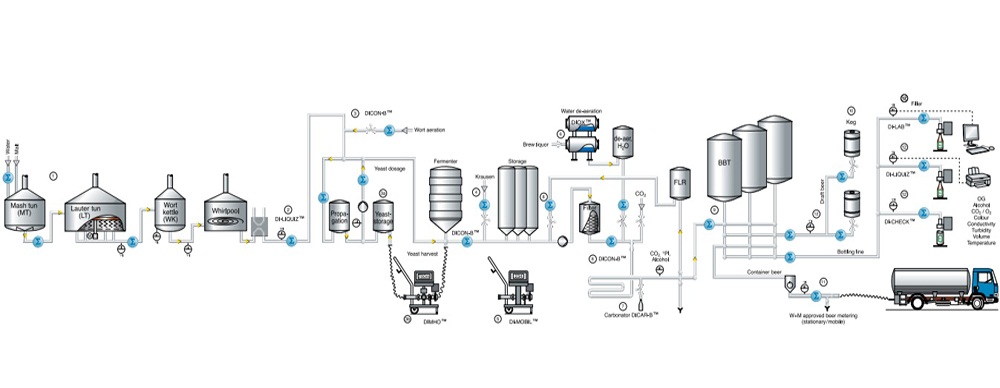

Process validation:

In order to make optimum use of personnel and technical resources, it is wise to plan early for validation projects. It is necessary to optimally coordinate the development, processes, product characterization, production and quality assurance in order to achieve the best possible overall project performance that leaves no gaps and avoids redundancies.

We support you in the implementation of Quality by Design (QbD) with the most important tools that are necessary for this: Design of Experiments (DoE) and conducting risk analyses. Appropriate definition and classification of your operating and acceptance ranges as well as the associated alert and action limits guarantee optimum process control.

- We provide support for the design and coordination of your validation project

- We provide consulting and coordination as well as the creation of risk analyses / assessments as well as validation documentation (source documents) for consistency studies.

- We offer stability studies for media, process buffers and process intermediates

We provide support in advance of your process validation project so that the requirements for a smooth validation process are assured:

- planning of GMP-compatible manufacturing plants

- plant qualification and computer validation

- process characterization

- validation of analytical methods

- preparation of SOPs

- training of your employees

Computer Validation:

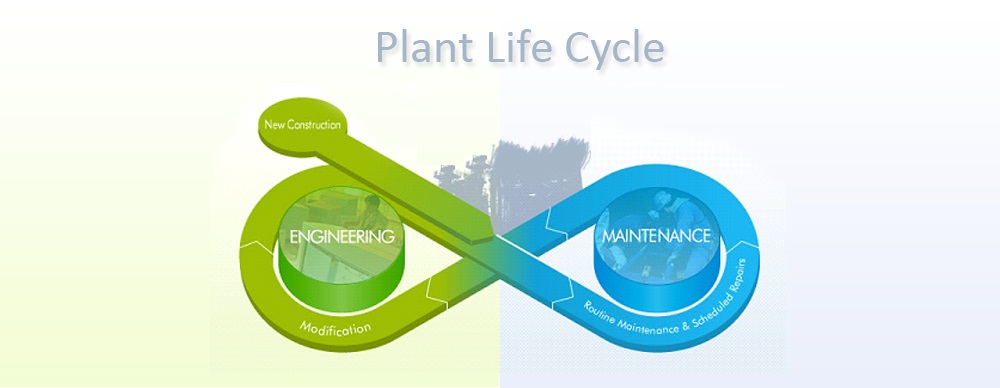

We coordinate the validation of your systems over the entire lifecycle.

Automated systems that affect the product quality and product safety of pharmaceuticals must comply with the requirements of the GMP rules and must be validated.

BioFluid plans and coordinates the validation of automated systems in accordance with EU and US rules and/or in accordance with the requirements of national authorities.

We define suitable validation measures for your system that are customized for the risk to the quality and safety of your products, and we coordinate the validation of your systems over the entire lifecycle.

We support you in the:

- definition of the GMP criticality of your systems (execution of system risk analyses)

- preparation of validation master plans according to GAMP5

- development of quality and project plans

- execution of functional risk analyses according to FMEA, risk-based definition of the scope of the test

- execution of 21CFR Part 11 assessments

- coordination of the test phase in the project

- coordination of the change management in the project

- assessment and revalidation of already existing systems

- preparation of the necessary SOPs

- training of your employees

- Make use of the consulting to maintain the validated status of your automated systems during operations (change management, configuration management)